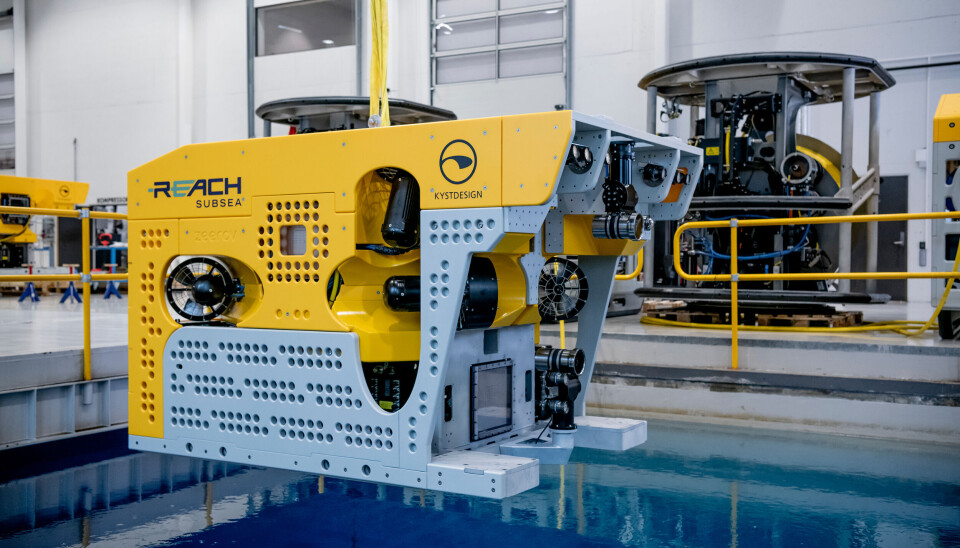

"Reach Remote" will be equipped with two state-of-the-art ROVs

Kystdesign AS has been responsible for the development, design and production of Reach Subsea's all-electric ROVs. “It is one of the biggest development projects we have had so far," says chief commercial officer Åge Holsbrekken.

Kystdesign originally started as a sole proprietorship within consultancy in 1997. In 1999 three more people joined the company, which was then transformed into a supplier for subsea equipment.

“Since then, there have been ROVs, which are our main product, but also tools for ROVs, various component deliveries and so on. It has been non-stop from the time this was an engineering company, which has now slowly but surely built up to also include production in all relevant disciplines,” explains Kystdesign CCO, Åge Holsbrekken.

The ROVs that have now been officially delivered to Reach Subsea will - like the ships themselves - be remotely controlled from shore.

“It is something we have good experience with before, so it is an advantage for our customers to be able to choose us. We delivered our first ROV back in 2002, and even that was designed for remote control from shore - as all our ROVs are,” says Holsbrekken.

The largest development project

“Two full ROV systems will be on board these ships. It is one of the biggest development projects we have had so far in Kystdesign,” says Holsbrekken.

The company has long seen it in the cards for all-electric ROVs to take over the market, but they have been clear that although several companies have developed electrical systems within ROVs in the past, the time was not quite ripe until the last few years.

“We knew that several people had done it before us, but we have deliberately chosen to be restrained. We decided to start the development of all-electric ROVs in 2020, before we had signed any contracts for deliveries. Only then did we feel that the time and technology were ripe for that leap, and we developed the electric motor that would drive the thrusters. We had then looked a lot at the electric car industry and further developed ourselves to be able to build on new technology from that industry aimed at what we do, and the time was finally ripe. When we signed the contract with Reach Subsea in January 2022, we accelerated our work and further developed what we were already well under way with.”

For the journey towards the green shift, all-electric ROVs could be of great importance.

“The environmental risk with hydraulic motors is that the hydraulic oil is put under high pressure. If you then experience a break in a hose during an operation, you will get a discharge of 100 litres of oil within two seconds. Since electric motors and junction boxes must also be filled with oil, you have the same amount of oil in all-electric systems, but here we are talking about low-pressure systems, and the consequences of a possible leak will be far less. In addition to this with reduced emissions, we also see great benefits with increased performance, better control options and increased operational reliability of these all-electric systems,” explains Holsbrekken.

First in the world

When Kystdesign first began the work, Reach Subsea had a rather meagre list of requirements that had to be met. The rest was up to Kystdesign.

“The ROVs were to have approximately 150 horsepower, approximately the same dimensions as our Supporter ROV in our range, approximately the same thruster power and, not least, we were to create a vessel that could operate continuously for 30 days without supervision. We decided early on not to take any shortcuts in this project. The ROV was to be developed with the best in electric motor technology with a high focus on performance, ease of use and operational safety. At Kystdesign, we have a vision to be a leader in ROV technology, which this project proves to be,” says Holsbrekken.

“What Reach Subsea is doing is without a doubt a rather resilient project. They are the first in the world to operate a complete working ROV system from a completely unmanned vessel, which is quite sensational.”

The ROVs can operate down to a depth of 2,000 metres and are supplied with a TMS (Tether Management System), which will ensure that the ROV has a lighter cable weight and is easier to manoeuvre.

“An ROV system with TMS weighs over six tonnes in air and approximately 1.5 tonnes in seawater. It will be a large and powerful equipment package for a relatively small vessel, which gives the customer big savings,” says Holsbrekken.

Submitted for testing

The two ROVs were delivered to Reach Subsea after an approved "factory acceptance test" just before the summer holidays, in June.

“When the customer is satisfied with the test we carry out, we sign the papers stating that the system meets the requirements of the contract - and the ROVs are delivered. In this phase, further project adaptations are on the agenda, where, among other things, a gravity sensor that Reach Subsea has in its portfolio will be tested. Now is the very last phase of preparations,” says Holsbrekken.

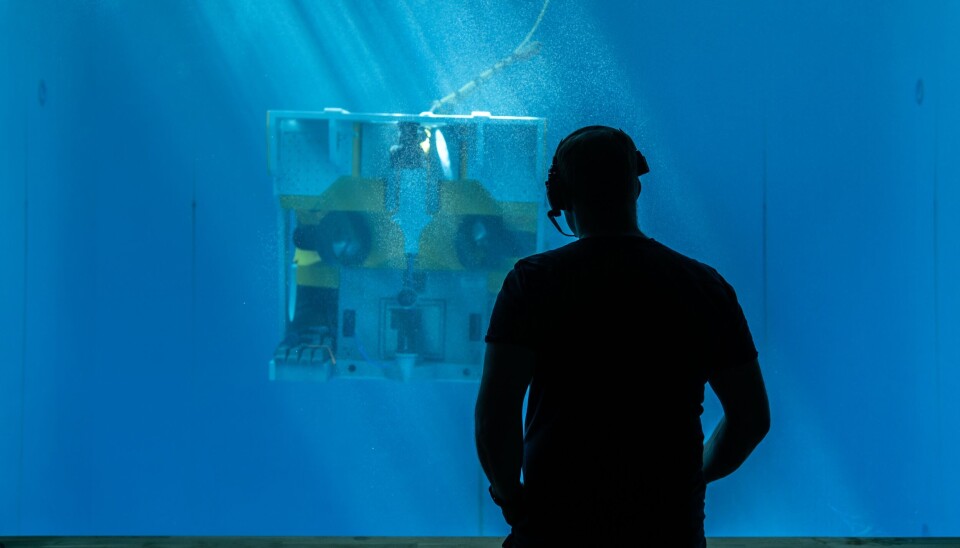

In 2016, Kystdesign moved to new, purpose-built premises with its own test pool.

“Before that time, we tested all our systems in the sea. It wasn't always as pleasant in the middle of winter, you could say,” says Holsbrekken with a laugh.

The test facilities at Kystdesign are now among the best that can be built, with a 10-metre-deep pool with an observation window at a depth of five metres, which means that you can keep a close watch from all angles.

“We are very happy with the room we have now, and the opportunities that the pool gives us,” says Holsbrekken.

Strong growth

Kystdesign has its head office and all its production facilities in Aksdal Næringspark in Tysvær municipality, just outside Haugesund. Today, the company has 60 employees.

The accounts for 2023 show that the company had a turnover of close to NOK 260.3 million and ended the year with a total profit of NOK 20.9 million. The result had doubled compared to the previous year, and turnover rose by over 45 per cent.

“There has been good growth. Especially in the last two years, we have grown a lot,” says Holsbrekken.

The company experienced a "dip" around the oil crisis in 2015/2016. At the time, an increase was expected from 2020 - but then the pandemic came.

“We really managed well through it all, as we got a foothold in both marine research and fish farming. For ocean research, we developed an ROV that can operate down to a depth of 6,000 metres. For fish farming, we developed an ROV that washed farming cages, an ROV of which we have now delivered close to 100 pieces so far, and which is the ROV model we have delivered by far the most to date,” says Holsbrekken.