This is “Medstraum”

At the end of June, MS "Medstraum" was delivered from Fjellstrand Yard to Kolumbus in Stavanger. The electric fast ferry is now being introduced on the route between Stavanger, Byøyene and Hommersåk.

It is Rogaland county's mobility company, Kolumbus, that owns "Medstraum". Rogaland county mayor, Marianne Chesak, is impressed by all the companies that have contributed from planning to construction of what will be the world's first all-electric fast boat.

“Soon, Kolumbus' commuter customers will be able to travel both environmentally friendly and almost silently on the sea to and from work and school.”

Traditional fast ferries running on fossil fuel are often referred to as emission worst-cases in short-haul shipping worldwide. Although Kolumbus has few fast boats in its fleet, the introduction of "Medstraum" will have a major positive impact on the climate account.

“We are very happy to finally deliver the world’s new flagship when it comes to fast ferries. Kolumbus aims to be far ahead in adopting new and environmentally friendly technology. The company currently has ten fast ferries, some ferries and 450 buses in operation. Even if "Medstraum" is to take over our least energy-demanding route, we will cut emissions equivalent to around 60 buses each year. That means 1,500 tonnes of CO2,” says Kolumbus project manager Mikal Dahle.

R&D Sales Manager at Fjellstrand Verft, Edmund Tolo, admits that it has been both challenging and instructive to build the new vessel, as it has never been done before.

“Fast ferries require a lot of energy, so it was important to make "Medstraum" both lighter and much more efficient than other vessels on the market. We have managed that, and that makes us both proud and happy. It is revolutionary that such a large vessel can travel at 23 knots for a full hour with only the help of electricity,” says Tolo.

Fjellstrand was the shipyard that built the world's first electric ferry, MF "Ampere", back in 2015. It was the start of an electric ferry revolution in Norway, and seven years later around 70 emission-free ferries are sailing in Norway. "Ampere" was also named Ship of The Year in 2014.

"Medstraum" has also received great international interest, says managing director of Maritime CleanTech, Hege Økland, who has initiated and established this industrial collaboration, which has received a lot of support from the EU.

“Actors all over the world are now looking at what we achieve in our maritime cluster. This could really be the start of a new industrial adventure. Not only have the partners in the project developed and demonstrated a new and emission-free propulsion system that can maintain higher speeds than before, we have also adopted completely new modular design and construction methods that will revolutionise the way we build vessels in the future. It is even better that it is Norwegian technology companies that are leading the way here,” says Økland.

The Norwegian industrial partners have taken inspiration from the car, aircraft and train industries during the construction of the vessel. The collaboration is supported by both the EU and Rogaland County Municipality.

“The modular way of thinking is absolutely central to the project. Now you can put together different ready-made modules, which can be built in different places to tailor boats for different purposes. It will be a bit like building with Lego. This will save both time and money in the design and construction phase,” says Økland. “It will also make it easier to get more vessels on to the market faster. In that way, we can more quickly meet future emissions requirements by replacing fossil fuelled fast ferries with all-electric ones - such as "Medstraum".”

The new vessel is 30 metres long and 9 metres wide and has a capacity of 150 passengers.

Equipment:

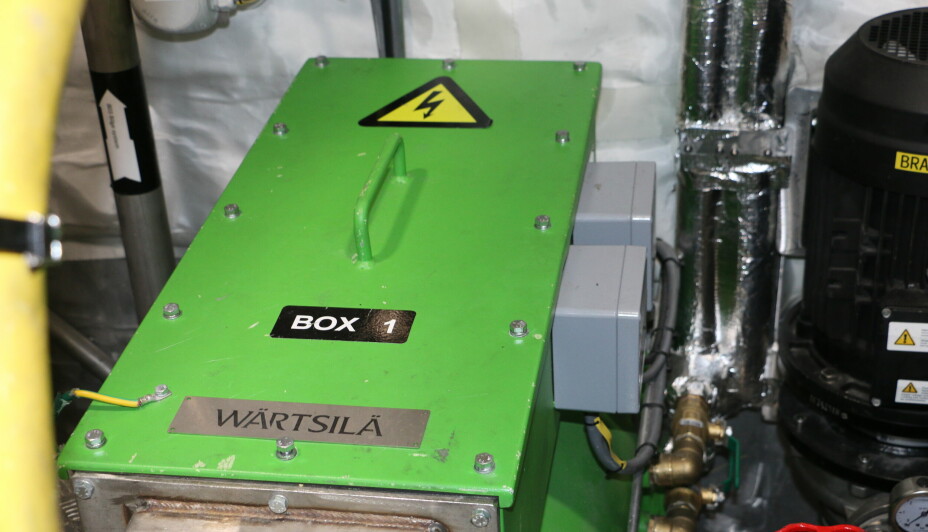

Propulsion engine and propulsion shafts are supplied by Wärtsilä. Servogear has supplied an HD 220 E gear with associated axle as well as rudder, brackets and their unique electric-flow propeller. The AC thruster comes from Sleipner Motor. Interceptors are from Humphree AB.

Brunvoll has supplied a remote control system.

The 1.5 MWh battery pack is of the Dolphin type from Corvus. Fans in the battery compartment are supplied by Novenco. The 1000V DC shore power system has been supplied by Austevoll Elektro, who have also supplied switchboards and charging cabinets on board.

Lanterns and searchlights are supplied by Glamox.

Electronic equipment is supplied by Ocean Electronics with components from Furuno, Simrad, Sailor, Hatteland and Scandinavian Micro System. PA equipment and speakers are provided by Zenitel.

Lifesaving equipment comes from Survitec. MBH Hydraulikk has supplied the windlass, while Sotra Anchor & Chain has supplied the anchor.

Libra-Plast has supplied waterproof and fireproof doors and hatches at "Medstraum". Windows come from SI Glass.

Gangways are supplied by Undertun. Passenger seats come from Modell Møbler AS. Furniture and furnishings are supplied by Fjorddesign.

Toilets and sewage systems are supplied by Jets Vacuum.

The fire extinguishing system is of the Novec type from Alf Lea & Co.

The vessel is classified by DNV, and painted with paint from Westing.